Home ⇒ Overview Courses ⇒ Electric drives

Electrical motors as energy converter

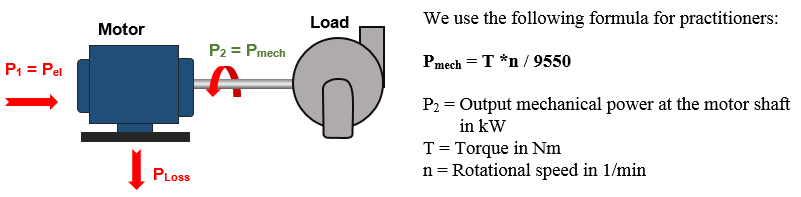

Electric motors convert electrical energy into mechanical energy. The engine drives a work machine and thus converts electrical energy into mechanical energy. Depending on the voltage, DC and AC machines are used in practice.

Criterias for the selection of an electric motor

- Power requirement of the working machine

- operating time and switching frequency

- Current type, mains voltage and mains frequency

- Speed and direction of rotation

- Size type

motor as an energy converter

The power loss has several reasons:

- Friction losses in the bearings and eventually the brushes

- Iron losses due to eddy currents and hysteresis losses

- Loss of excitation due to changes in the magnetic field

- Loss of the motor winding (ohmic and inductive resistance)

The efficiency η of an electric motor is given by the ratio of the mechanical output power Pmech (P2) to the electric input power Pelectr. (P1).

ƞ = P2 / P1 and PV = P1 - P2

Four-quadrant operation of electric motors

An engine can act as a motor, when the torque acts in the same direction as the speed (CW or CCW). When torque and speed are opposite, then the motor acts like a brake. With appropriate electronics, this braking energy can be fed back into the grid - keyword "Regenerative Braking".

Four Quandrant Operation of electric motors