Home ⇒ Overview Courses ⇒ Electropneumatics ⇒ Reed

Reed sensors - Functioning and appliance

Reed-sensors, also known as magnetic sensor, in shorted Reed1, are binary non-contact sensors, which have a wide range of applications in addition to the electric pneumatics. The Reeds were developed by the 'Bell Laps'-company at the end of 1930. From about 1940 the industrial use began.

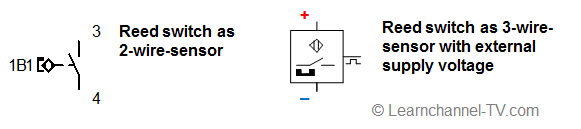

Symbol - Reed switch

Function: The structure is simple: a hermetically sealed reed consisting of iron-nickel alloy, forming a normally opened or normally closed contact. A magnet approaching this ferromagnetic reed leads to switching.

Reed - how does it work

Because of the hermetic seal and the contactless switching the reed sensors have some obviously great advantages to the mechanical switches. It´s difficult to find concrete specifications from manufacturers because of product liability, but the product life begins at about 1 million switching cycles. The switching time is about 0.2 ms.

Reed sensor animation

The applications for Reed's are varied. In the electropneumatics these magnetic switches are used primarily for detecting the end position of cylinders:

Example circuit: Pressing the S1 button the cylinder extends and automatically retracts upon reaching the front end position. In the animation below, the reed switches directly a solenoid valve. Another possibility would be the use of a relay if the switching power of the reed is not sufficient.

Reed example circuit